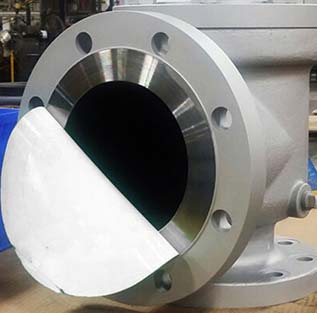

WHAT IS EPOXY COATED FLANGE?

The chief application of epoxy is as a coating on various metal products including pipes, flanges or even fasteners. The polymerization of epoxides forms an epoxy resin, which in turn is applied on the Epoxy Coated Flanges. The polymer is crosslinked, when this epoxy resin is thermostatically heated. The coating itself consists of two components. Firstly it is a resin and the next component is a hardener, which improves the durability of the Epoxy Coated Blind Flange.

TYPES OF EPOXY COATING USED FOR FLANGES?

The most common type of coating used on flanges is FBE, because of the several benefits they offer. For instance, the ASTM A105 FBE Coated Flanges have improved corrosion resistance and are much more durable than bare flanges, especially in industrial sectors like the oil and gas industry, or in the conveyance of potable water.

HOW LONG DOES EPOXY COATING LAST?

Since the Carbon Steel Flange PE Coating applied is a thermoset one, it is considered to be a permanent one.

EPOXY LINED FLANGES SPECIFICATIONS

Epoxy Coated Ductile Iron Pipe Flanges drilled To Pn10, ISO/ Din 2501

| Size Range | 1/2"- 48" (15 NB - 1200NB) DN10~DN5000 |

| Manufacturing Standards | ANSI/ ASA/ ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, ASME/ ASA/ ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API605, API7S-15, API7S-43, |

| Pressure Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Coating | Oil Black Paint, Zinc Plated, Yellow Transparent, Anti-rust Paint, Cold and Hot Dip Galvanized Coated Flange |

| Epoxy Coated Carbon Steel Flange grades |

|

STEEL FLANGE POLYPROPYLENE COATING DIMENSIONS

PP Coated Steel Backing Flange, (metric)

30% glass-fibre PP reinforced with steel ring

UV-resistant used for outdoor use

Dimensions accordnace to EN 1092, ISO 7005, BS 4504, DIN 2501

Bolt circle PN10 - 16

PP Coated Steel Backing Flange, (ANSI)

30% glass-fibre PP reinforced with steel ring

UV-resistant used for outdoor use

Dimensions accordnace to ANSI / ASA/ ASME B16.5 class 150, BS 1560, ASTM D4024, BS EN 1759

Bolt circle class 150

Dimensions & Size range

| DN | D (MM) | ISO PN |

|---|---|---|

| 15 | 20 | 10/16 |

| 20 | 25 | 10/16 |

| 25 | 32 | 10/16 |

| 32 | 40 | 10/16 |

| 40 | 50 | 10/16 |

| 50 | 63 | 10/16 |

| 65 | 75 | 10/16 |

| 80 | 90 | 10/16 |

| 100 | 110 | 10/16 |

| 100 | 125 | 10/16 |

| 125 | 140 | 10/16 |

| 150 | 160 | 10/16 |

| 200 | 200 | 10 |

| 200 | 225 | 10 |

| 200 | 200 | 16 |

| 200 | 225 | 16 |

| 250 | 250 | 10 |

| 250 | 280 | 10 |

| 250 | 250 | 16 |

| 250 | 280 | 16 |

| 300 | 315 | 10 |

| 300 | 315 | 16 |

| 350 | 355 | 10 |

| 350 | 355 | 16 |

| 400 | 400 | 10 |

| 400 | 400 | 16 |

PN 16 COATED PP FLANGES METRIC WEIGHT CHART

| d | DN | D | a | k | b | ı | Bolt | Number of Holes | Weight | Box |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | Piece |

| 20 | 15 | 95 | 28 | 65 | 12 | 14 | M12 | 4 | 0.232 | 85 |

| 25 | 20 | 105 | 34 | 75 | 12 | 14 | M12 | 4 | 0.288 | 68 |

| 32 | 25 | 115 | 42 | 85 | 16 | 14 | M12 | 4 | 0.544 | 52 |

| 40 | 32 | 140 | 51 | 100 | 16 | 18 | M16 | 4 | 0.836 | 20 |

| 50 | 40 | 150 | 62 | 110 | 18 | 18 | M16 | 4 | 0.902 | 15 |

| 63 | 50 | 165 | 78 | 125 | 18 | 18 | M16 | 4 | 1.074 | 15 |

| 75 | 65 | 188 | 92 | 145 | 18 | 18 | M16 | 4 | 1.368 | 15 |

| 90 | 80 | 204 | 108 | 160 | 20 | 18 | M16 | 8 | 1.516 | 10 |

| 110 | 100 | 224 | 128 | 180 | 20 | 18 | M16 | 8 | 1.960 | 10 |

| 125 | 100 | 224 | 135 | 180 | 20 | 18 | M16 | 8 | 1.938 | 10 |

| 140 | 125 | 252 | 158 | 210 | 24 | 18 | M16 | 8 | 2.866 | 6 |

| 160 | 150 | 285 | 178 | 240 | 24 | 22 | M20 | 8 | 3.576 | 6 |

| 180 | 150 | 285 | 188 | 240 | 24 | 22 | M20 | 8 | 3.298 | 6 |

| 200 | 200 | 340 | 235 | 295 | 27 | 22 | M20 | 12 | 5.032 | 4 |

| 225 | 200 | 340 | 238 | 295 | 27 | 22 | M20 | 12 | 4.900 | 4 |

| 250 | 250 | 419 | 288 | 355 | 32 | 26 | M24 | 12 | 10.182 | 2 |

| 280 | 250 | 419 | 294 | 355 | 32 | 26 | M24 | 12 | 9.860 | 2 |

| 315 | 300 | 478 | 338 | 410 | 34 | 26 | M24 | 12 | 13.150 | 2 |

| 355 | 350 | 532 | 376 | 470 | 42 | 26 | M24 | 16 | 22.200 | 1 |

| 400 | 400 | 592 | 430 | 525 | 46 | 30 | M27 | 16 | 26.214 | 1 |

CARBON STEEL FLANGE FUSION BONDED EPOXY COATING PROCESS

The process of coating application can be simply broken down into three steps. The first step would include cleaning the flange following which it is to be heated at the desired temperature. Once the flange is heated, a coating is applied to it. The last step involves curing the ASTM A350 LF2 Epoxy Coated Slip On Flange to permanently set it.

ADVANTAGES AND DISADVANTAGES OF FBE COATED FLANGES

Besides having a lower rate of corrosion, these ASME B16.5 Epoxy Lined Flanges perform much better as they are less likely to fail by stress-related cracking. Although there are some concerns with regards to the carcinogenic factors linking these coatings, they are known to not only be eco-friendly but also non-toxic.

TYPES OF COATED FLANGE

Fusion Bonded Epoxy Coating Flange and Pe Coated Steel Flanges at factory price

|  |

| Epoxy Coated Ductile Iron Pipe Flange Galvanized ASTM A105 Carbon Steel Blind Flange, RF, 300LB | Fusion Bonded Epoxy Coating Blind Flange Pe Coating ASTM A350 Flat Face Blind Flange |

|  |

| Flat Face Flange Coating A182 Alloy Steel Spectacle Blind Flange, FBE Lined | Flange Pe Coating FBE Coating ASTM A694 Forged Steel Blind Flange |

|  |

| Pe Coated Carbon Steel Flange FBE Coated Dual SS Blind Flange, RF, PN20, DN80 | A182 Epoxy Coated Alloy Steel Flanges ASTM A182 F304 Epoxy Coating Lapped Joint Flange, DN25, ANSI B16.5 |

|  |

| FBE Lined API 6A flanges ANSI B16.5 CS Galvanized Lap Joint Flange, Stub Ends | Epoxy Coated ASTM A105 Flange Fusion Bonded Epoxy Coating Carbon Steel Lap Joint Flange |

|  |

| ASTM A350 LF2 FBE Lined Flange FBE Coated ASTM A105 Orifice Flange, PN50, DN80, SCH 80 | Epoxy coating on flange face Epoxy Coating SCH STD 900LB Orifice Welded Neck Flanges |

|  |

| DN300, PN50 Underground Flange Coating FBE Lined Weld Neck Orifice Flange, 300#, 12 Inch, RF | 24 Inch SCH 80 Epoxy Coated ASTM A105N Weld Neck Flange FBE Coating ASTM A105 SO Flange, 300LB, 4 Inch, EN1092-1 |