API 6A standard is developed for the American Petroleum Institute. The API 6A specification shares many characteristics with ANSI/ASME flanges. Despite being dimensionally similar, their minimal design requirements for operating pressure begin in the 2000PSI. Certain jobs require the use of pressure classes as high as the 6BX 20000PSI, though this is much less common than the typical 6B range of 5000PSI and below.

All API flanges require ring type joint facings with the proper gaskets for optimal integrity of their application.This higher-pressure base requirement is due to their overwhelmingly popular use in petrochemical / oilfield applications of a volatile nature. Upstream assemblies with API flanges consist of wellheads, drilling equipment, and much more. The downstream sectors of refinery and processing also require these flanges for the development of crude oil into products for the everyday consumer.

6B flanges are of the ring joint type and are not designed for face-to-face make-up.The connection make-up bolting force reacts on the metallic ring gasket.The size from 2-1/16″ to 21-1/4″ and pressure 2000PSI,3000PSI and 5000PSI.

6BX flanges are of the ring joint type and designed with a raised face. Depending on the tolerances, the connection make-up bolting force may react on the raised face of the flange when the gasket has been properly seated. This support prevents damage to the flange or gasket from excessive bolt torque.The size from 2-1/16″ to 21-1/4″ and pressure 10000PSI,15000PSI and 20000PSI.

SIZE:

1.13/16"-30"

CLASS:

13.8 MPA (2000psi),20.7 MPA (3000psi),34.5 MPA (5000psi),69.0 MPA (10000psi),103.5 MPA (15000psi),138.0 MPA (20000psi).

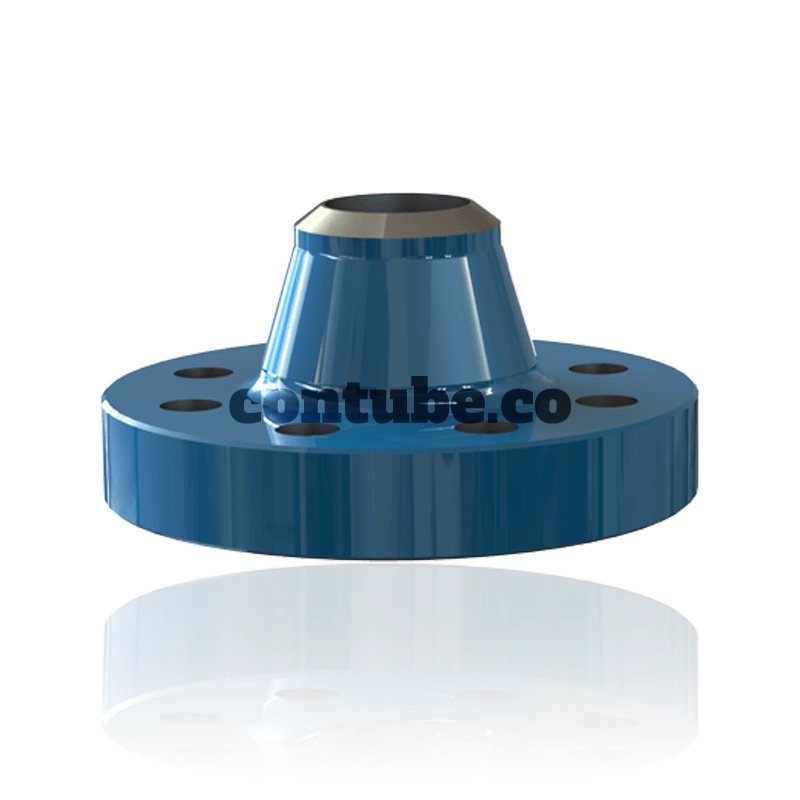

FLANGE TYPE:

Welding neck,Blind.

MATERIAL:

ASTM A105,ASTM A350 Gr. LF2,ASTM A350 Gr. LF6 Cl.1,ASTM A350 Gr. LF3,ASTM A350 Gr. LF6 Cl.2,ASTM A350 Gr. LF1 Cl.1,ASTM A182 Gr. F1,ASTM A182 Gr. F2,ASTM A182 Gr. F11 Cl.2,ASTM A182 Gr. F22 Cl.3,ASTM A182 Gr. F5a,ASTM A182 Gr. F9,ASTM A182 Gr. F91,ASTM A182 Gr. F12 Cl.2,ASTM A182 Gr. F5,ASTM A182 Gr. F92,ASTM A182 Gr. F304,ASTM A182 Gr. F304H,ASTM A182 Gr. F316,ASTM A182 Gr. F316H,ASTM A182 Gr. F317,ASTM A182 Gr. F304L,ASTM A182 Gr. F316L,ASTM A182 Gr. F317L,ASTM A182 Gr. F321,ASTM A182 Gr. F321H,ASTM A182 Gr. F347,ASTM A182 Gr. F347H,ASTM A182 Gr. F348,ASTM A182 Gr. F348H,ASTM A182 Gr. F310,ASTM A182 Gr. F44,ASTM A182 Gr. F51,ASTM A182 Gr. F53,ASTM A182 Gr. F55,ASTM B462 Gr. N08020,ASTM B564 Gr. N02200,ASTM B564 Gr. N04400,ASTM B564 Gr. N06600,ASTM B564 Gr. N08800,ASTM B462 Gr. N10665,ASTM B462 Gr. N10675,ASTM B462 Gr. N10276,ASTM B564 Gr. N06625,ASTM B564 Gr. N08825,ASTM B462 Gr. N06022,ASTM B462 Gr. N06200,ASTM B572 Gr. R30556,ASTM A479 Gr. N08904,ASTM B462 Gr. N08367,ASTM B564 Gr. N08031,ASTM B462 Gr. N06030,ASTM B462 Gr. N06035,ASTM B564 Gr. N08810,ASTM B511 Gr. N08330,ASTM B564 Gr. N06230

SURFACE TREATMENT:

Epoxy Coated,Coated With Anti-Rust Oil Coating,Transparent paint,Black Paint,Electrogalvanizing,Hot dip galvanizing,Powder coating,Electropolishing,Dacromet.

END FLANGE FACINGS:

Ring Joint Face

CONNECTION TYPE:

Welding

PRODUCTION TECHNIQUE:

Free forging flange,Die forging flange,Ring rolling forging flange.